- Home

- About Us

- Industries

- Agritech & Smart Farming

- Aquariums & Zoos

- Art & Cultural Exhibitions

- Automotive & Transportation

- Broadcasting & News

- Construction & Real Estate

- Corporate & Offices

- Cultural Heritage & Preservation

- Cybersecurity Operations

- Digital Content Creation & Media

- E-commerce & Online Retail

- Education

- Energy & Utilities

- Entertainment & Media

- Entertainment Arcades & Amusement

- Environmental Monitoring

- Event Management & Conferences

- Fashion & Apparel Retail

- Fashion Retail & E-commerce

- Finance & Banking

- Financial Trading & Stock Exchanges

- Fitness & Wellness

- Food & Beverage

- Food Processing & Manufacturing

- Gaming, Casinos, & Hospitality

- Government & Public Spaces

- Healthcare

- Hospitality & Event Venues

- Insurance

- Legal & Judicial

- Libraries & Community Centers

- Logistics & Supply Chain

- Luxury Cruise & Maritime

- Manufacturing & Industrial

- Meteorology & Climate Research

- Military & Defense

- Mining & Extraction

- Museums & Cultural Centers

- Non-Profit Organizations

- Oil & Gas Industry

- Professional Training & Development

- Public Health & Awareness

- Public Parks & Recreation Areas

- Public Safety & Law Enforcement

- Public Transportation

- Rehabilitation Centers

- Religious & Worship Spaces

- Renewable Energy

- Retail & Shopping Malls

- Retail Banking

- Security & Surveillance

- Social Media & Digital Marketing

- Sports & Stadiums

- Smart Cities & Urban Planning

- Supply Chain & Inventory

- Television & Film Production

- Travel & Hospitality

- FAQ

- Contact Us

- Home

- About Us

- Industries

- Agritech & Smart Farming

- Aquariums & Zoos

- Art & Cultural Exhibitions

- Automotive & Transportation

- Broadcasting & News

- Construction & Real Estate

- Corporate & Offices

- Cultural Heritage & Preservation

- Cybersecurity Operations

- Digital Content Creation & Media

- E-commerce & Online Retail

- Education

- Energy & Utilities

- Entertainment & Media

- Entertainment Arcades & Amusement

- Environmental Monitoring

- Event Management & Conferences

- Fashion & Apparel Retail

- Fashion Retail & E-commerce

- Finance & Banking

- Financial Trading & Stock Exchanges

- Fitness & Wellness

- Food & Beverage

- Food Processing & Manufacturing

- Gaming, Casinos, & Hospitality

- Government & Public Spaces

- Healthcare

- Hospitality & Event Venues

- Insurance

- Legal & Judicial

- Libraries & Community Centers

- Logistics & Supply Chain

- Luxury Cruise & Maritime

- Manufacturing & Industrial

- Meteorology & Climate Research

- Military & Defense

- Mining & Extraction

- Museums & Cultural Centers

- Non-Profit Organizations

- Oil & Gas Industry

- Professional Training & Development

- Public Health & Awareness

- Public Parks & Recreation Areas

- Public Safety & Law Enforcement

- Public Transportation

- Rehabilitation Centers

- Religious & Worship Spaces

- Renewable Energy

- Retail & Shopping Malls

- Retail Banking

- Security & Surveillance

- Social Media & Digital Marketing

- Sports & Stadiums

- Smart Cities & Urban Planning

- Supply Chain & Inventory

- Television & Film Production

- Travel & Hospitality

- FAQ

- Contact Us

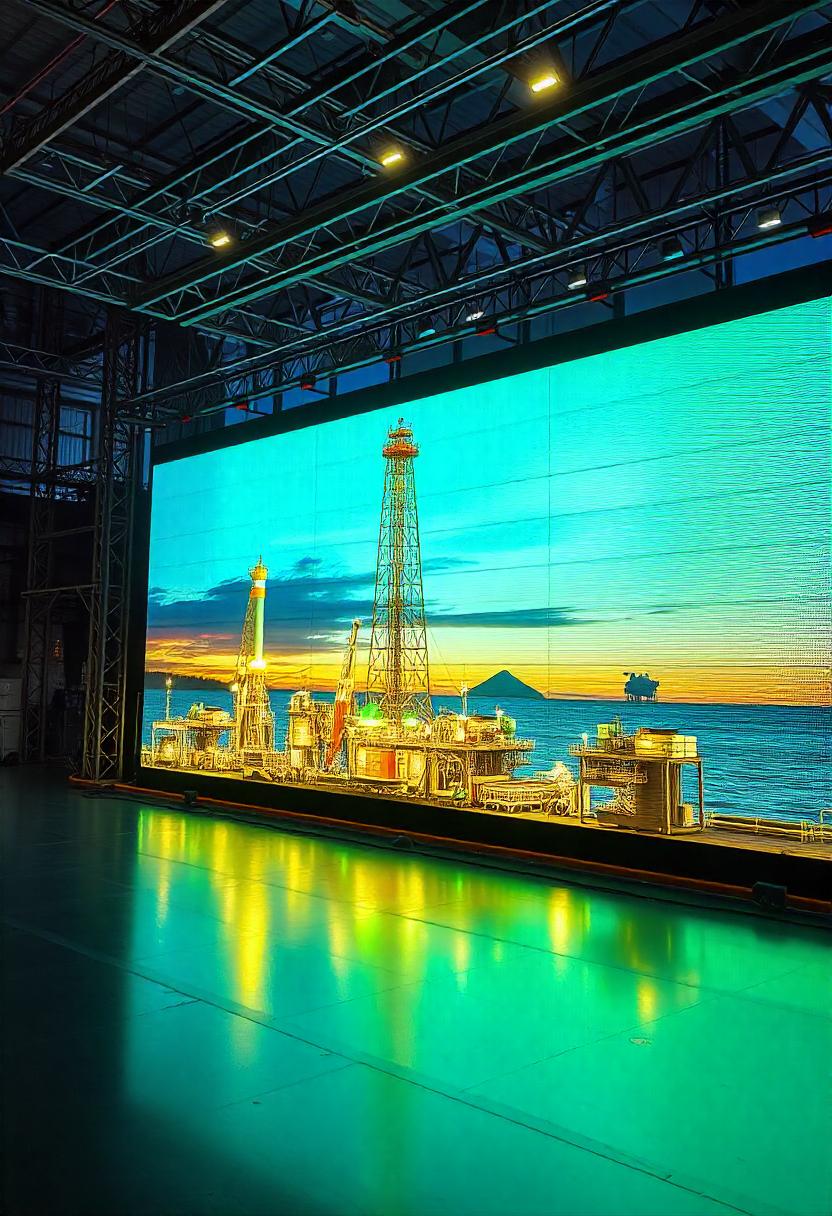

Oil & Gas Industry

Uses Of Led Display For Oil & Gas Industry

Active LED displays are increasingly being used in the oil and gas industry for a variety of applications ranging from operations monitoring to safety communication. These displays provide real-time data visualization, enhance decision-making, improve safety protocols, and contribute to more efficient management of resources in the sector.

Advantages of Active LED Displays in the Oil and Gas Industry:

- Real-Time Data Visualization: LED displays allow for the instant visualization of critical operational data, such as production metrics, safety alerts, and equipment status.

- Durability and Reliability: Designed to withstand harsh industrial environments, active LED displays are durable, resistant to temperature fluctuations, moisture, and vibrations.

- Energy Efficiency: LEDs consume less power and have a longer lifespan compared to traditional displays, making them cost-effective over the long term.

- High Visibility: The brightness and clarity of LED displays ensure that they are visible in all lighting conditions, including harsh or low-light environments typical in offshore platforms, refineries, or on-site operations.

- Customizable Display Sizes and Formats: These displays can be tailored to fit any space, whether it’s a control room, field location, or outdoor facility, providing flexibility for various industrial needs.

Applications in the Oil and Gas Industry:

- Control Room Displays

- Purpose: To provide operators with live data from multiple sources in a centralized location.

- Content Ideas: Display key performance indicators (KPIs), real-time production data, well status, pressure levels, and other operational metrics. LED screens can show graphs, gauges, and live feeds of production systems for enhanced monitoring and analysis.

- Safety and Alert Systems

- Purpose: To communicate critical safety information quickly and effectively.

- Content Ideas: Use LED displays for emergency alerts, gas leak warnings, fire alarms, or other safety-critical messages. These displays can be placed in strategic locations throughout the facility or on offshore rigs to ensure that safety notifications are visible to all personnel.

- Remote Monitoring of Oil Fields

- Purpose: To monitor remote oil fields and wellheads in real time.

- Content Ideas: LED displays are ideal for monitoring data from sensors and systems installed at oil fields, allowing operators to track production, equipment status, and environmental conditions remotely. This can include monitoring offshore platforms, pipelines, or land-based oil rigs.

- Equipment Status and Maintenance Scheduling

- Purpose: To track the health and maintenance needs of equipment.

- Content Ideas: Display live data regarding the status of critical machinery such as pumps, compressors, and turbines. LED displays can show alerts when equipment needs servicing, helping maintenance teams plan work and reduce unplanned downtime.

- Real-Time Environmental Monitoring

- Purpose: To monitor environmental impact and comply with regulatory requirements.

- Content Ideas: Display real-time environmental data such as emissions, water quality, or temperature monitoring on LED screens in control rooms. These displays can help ensure compliance with environmental standards and safety regulations while enabling immediate corrective actions if necessary.

- Offshore and On-Site Operational Displays

- Purpose: To provide up-to-date operational data in challenging environments.

- Content Ideas: Use ruggedized LED screens for monitoring operations in remote or offshore locations where high visibility and durability are critical. These displays can show operational data such as production levels, equipment performance, and system diagnostics in real time.

- Training and Simulation Displays

- Purpose: To provide visual aids for training personnel.

- Content Ideas: LED displays can be used in training simulators to show process flows, safety drills, and other educational materials in a clear and interactive manner. These displays can enhance training programs by providing realistic simulations for operators and emergency response teams.

- Pipeline Monitoring

- Purpose: To monitor pipeline integrity and operational status.

- Content Ideas: Active LED displays can show real-time data from sensors placed along pipelines, such as pressure levels, flow rates, and temperature. They can also highlight areas that may require inspection or maintenance, improving pipeline safety and efficiency.

- Operational Dashboards

- Purpose: To centralize key data for decision-makers.

- Content Ideas: Display a centralized dashboard showing real-time production data, operational efficiency, and financial metrics. These dashboards can be used by senior management or operational teams to make data-driven decisions on production strategies, risk management, and resource allocation.

- Public Communication and Advertising

- Purpose: To promote corporate responsibility, community engagement, and brand visibility.

- Content Ideas: Display public-facing content such as corporate social responsibility (CSR) initiatives, environmental sustainability efforts, and community programs. LED screens can be used for outdoor signage or in public-facing areas of corporate offices to engage stakeholders.

Features

- List Item

- List Item

- List Item

- List Item

Advantages

- List Item

- List Item

- List Item

- List Item

Placement Tips:

- Control Rooms: Place large LED displays in control rooms where real-time data from various sources can be easily viewed by operators. These displays should be positioned at eye level to ensure maximum visibility.

- Production Facilities: Install LED displays in key operational areas such as drilling sites, processing plants, and refinery floors to provide staff with real-time data on equipment status, safety, and environmental factors.

- Safety Zones: In hazardous or emergency-prone areas, such as offshore rigs or refineries, use LED displays to show safety alerts, evacuation procedures, and emergency response instructions.

- Outdoor Locations: Use weather-resistant LED displays for outdoor use in remote or offshore locations. These displays should be designed to withstand harsh environmental conditions such as extreme temperatures, humidity, and exposure to the elements.

- Field Locations: In oil fields or refineries, place smaller, portable LED displays at strategic points for monitoring specific equipment, processes, or environmental factors. These displays can be mobile and provide localized insights into operations.

Key Benefits in the Oil and Gas Industry:

- Enhanced Operational Efficiency: LED displays facilitate the real-time monitoring of equipment and operations, enabling teams to respond faster to issues and optimize performance.

- Improved Safety: Active LED displays ensure that safety information, such as hazard alerts and emergency instructions, are visible at all times, improving the overall safety of personnel in high-risk environments.

- Remote Monitoring Capabilities: LED displays allow for the monitoring of remote assets and operations, such as offshore platforms and pipelines, ensuring continuous oversight without the need for constant physical presence.

- Environmental Monitoring: Real-time environmental data visualization helps ensure compliance with regulations and quickly identify any environmental hazards, allowing for timely mitigation.

- Cost Savings: By improving operational efficiency, reducing downtime, and optimizing maintenance, LED displays can help reduce operational costs in the long run.

Conclusion

In the oil and gas industry, active LED displays are indispensable for enhancing real-time data visualization, improving safety communication, and optimizing operations. These displays are invaluable for monitoring critical operations, ensuring regulatory compliance, and maintaining smooth workflows across the complex and often hazardous environments of the oil and gas sector.

illuminits LED Walls?

Technology

There are three primary LED video wall technologies: ultra-narrow bezel LCD, rear-projection cubes, and direct-view LED displays. Ultra-narrow bezel LCD is the most cost-effective option.

Size

The great thing about illuminits video walls is that they are modular, so you can get them in any size or aspect ratio you want.

Support

The heavier the video wall system becomes, the more panels there are. This puts additional strain on the infrastructure that supports it. illuinits offers the best in-time assistance.

Service

Even high-definition video walls can have problems. This can be a minor or major issue. As a result, Aero provides a variety of comprehensive service packages that ensure minimal downtime at a low cost. Types Of LED Displays